|

During my research into hydrogen production using

a distilled water{1} electrolyte, I noted

something I considered strange during a series of tests covering

the point in time at when H2 gas first started forming

on the cathode. I was not interested in the voltage or current at

which formation began, rather I wanted to know if the gas

formation started uniformly over the entire electrode or if it

started at a specific location or locations alone the length of

electrode. I had noted for some time that initial production was

not uniform, although at first my assumption was the observation

was possibly due to surface imperfections of the electrode

itself. I must note that I was indeed taking into consideration

the potential effect of V/cm, which appeared inadequate in

explaining the time lag involved for the entire electrode to

become part of the overall gas production.

Once gas production was fully involved on an

electrode, it became extremely difficult to determine if symmetry

of release existed. My objective in looking closer was to

determine if the electrode geometry could in some way affect the

overall gas production and efficiency. In short would a specific

electrode shape allow for an increase in overall production

efficiency?

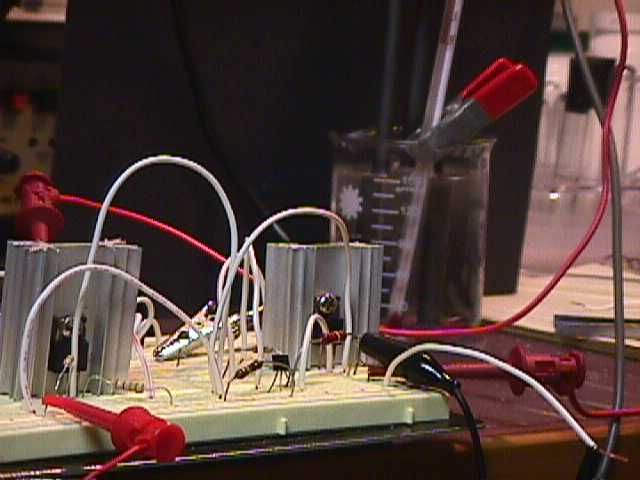

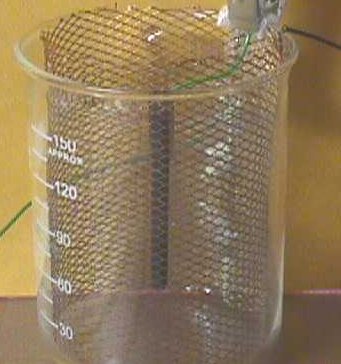

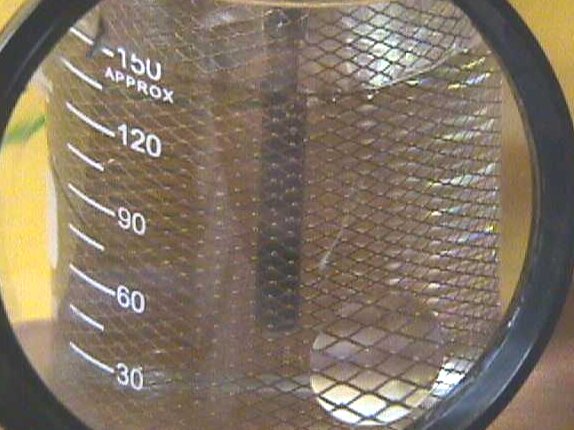

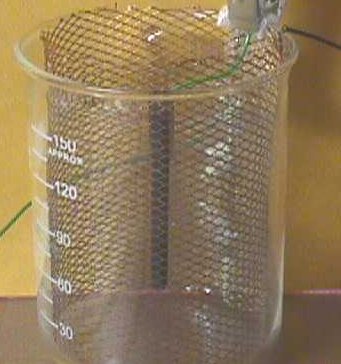

My first observation was made using a

Carbon (Graphite){11} rod for the cathode and a

Copper circular screen for the anode. It should be noted that my

interest was not in the impact of using Copper in the test cell

(Cu is not recommended because of chemical reactions it takes

part in during electrolysis). This arrangement was used primarily

for convenience and did not affect my conclusion. The test cell

is shown in the following photo, the cell consisted of a 150 mL

lab beaker filled with ordinary tap water (not my normal

distilled electrolyte) and electrodes as described above.

The beaker was filled to just 2 mm below the top

of the carbon{11} electrode. Once filled the

beaker was allowed to sit without a cover for 30 minutes before

testing, allowing for the contents to temperature stabilize and

some degassing.

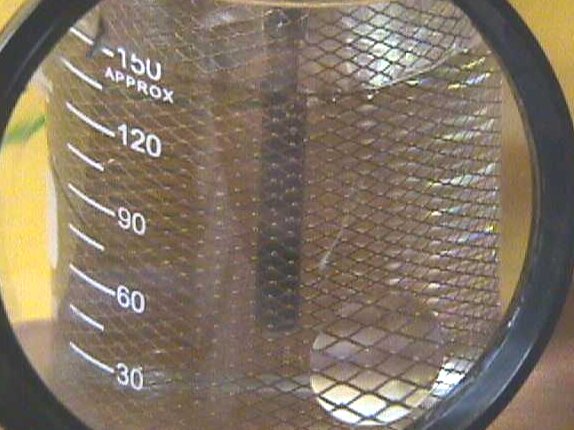

The test was quite simple in nature,

start applying voltage in discreet steps while observing the

carbon cathode with a 4X magnifier for the first sign of gas

formation. The setup is shown in the following photo.

The following conditions were not taken into

consideration during my tests because they would not have a

direct impact on the results, primarily because any contribution

from these factors would be easily observable; ambient

temperature, cells temperature, offset if any in the distances

between the anode and cathode.

The period of each test was short enough that

temperature layers did not form. Repeated tests were conducted

with a new liquid sample and new electrodes.

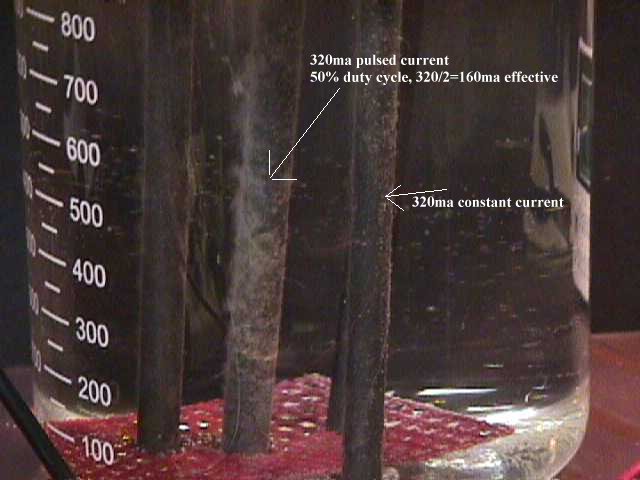

The following photo (plus simulated

gas bubbles, as the initial bubbles were to small to be

photographed) shows the location on the carbon rod where gas

formation first begins. The initial bubbles are small and start

spreading rapidly up the rod as the process continues.

A model we developed attempting to

explaining our first observations..

First consider the carbon rod from an electrical

resistance point of view in free space, if we started measuring

the rods resistance from point *a (our reference point) checking

at evenly spaced points (*b,*c,*d) and ending at *e, we would see

an increasing resistance over the rod length and

point *E, the end of the rod, we would measure the highest

resistance. Using this view and considering only resistance, one

might think that the top most point of the rod or point *A would

be the most vigorous point for gas production if the rod were

considered an infinite number of resistors in parallel.

The resistance at point *e on the rod

now becomes Rt = 1/(1/R(A) + 1/R(n)...

). What has happened is we now see a total reversal in

resistance, point *E is now the lowest and point *A is the

highest. Therefore under this set of conditions we would have the

highest available current at point *e (very tip of the rod) and

the least available current at point *a.

With this view in

mind the question raised is; Could increased gas production and

or efficiency (while holding cell input constant) be obtained by

proper selection of different electrode geometries? Currently

plates, disks and rods are standard shapes used for electrolyzing

electrodes, but are these efficient designs? We think not and

have experimentally demonstrated that different electrode

geometries do indeed have significant effect on gas production

efficiency.

After testing with rods, plates and disks it did

not take long to envision what would be the most efficient

electrode shape, a solid conductive sphere.

To confirm this I performed a test with a steel

ball bearing fastened with epoxy into a plastic syringe so that

approximately one half of the bearing surface was exposed to the

electrolyte. A pressure connection was made inside of the syringe

so that only the steel was exposed. The following photo shows the

test configuration.

The same test procedure was used where

the voltage was increased in steps from zero until the first

indication of gas formation. We were able to capture this event

as shown in the following photo, because the bubbles were much

larger and almost covered the entire area of the exposed steel

bearing instantaneously. Granted, the surface (exposed area) of

the steel ball is much smaller than the total surface area of the

initial carbon rods, therefore the voltage potential per

centimeter is indeed higher, yet we later confirmed that the

shape was indeed advantageous over different shapes containing

similar exposed surface area.

The

theoretical optimum electrode would be a solid conductive

sphere{2} where the driving voltage

could be supplied at the exact center (core) of the sphere. The

following graphic shows why this is the ideal shape when looking

at resistance distribution.

The ideal sphere would consist of an infinite

number of resistances in parallel from the center where the

voltage is applied. This would mean that every external point on

the sphere would present the same potential pressure as every

other point. This concept is very much different from what is

seen with rods, plates and disks.

Electrode geometry and material composition

additionally impacts gas bubble retention on electrode surfaces

and overall current density resulting from the insulated surface

area. When gas bubbles are retained (built up) on the surface of

an electrode, that surface area is temporarily removed (until

bubbles are released) from contributing to continued electrolysis

because the gas bubble is isolating that portion of the surface

from exposure to the surrounding H2O. This is observed

when input current is monitored and found to gradually build

until the surface of an electrode starts losing surface area from

retained gas bubbles, at which point the input current will be

observed to begin to decreasing and continue to decrease as

additional surface area is removed from participation in the

reaction.

One might think of a number of ways in which to

dislodge these retained gas bubbles, although the more common and

easily implemented methods do present a down side to what should

be beneficial. Two possible methods (stirring &

re-circulating) the H2O electrolyte.

Indeed, stirring the H2O around the

area of the electrode does aid in the removal of gas bubbles from

the electrode surface and additionally breaks up the various

thermal layers built up within the cell, yet it also disrupts the

ion distribution around the electrode. Disruption of the ion

density around the electrode while knocking gas bubbles free will

temporarily cause a small spike in gas output and a decrease in

input current resulting from the disruption of the surrounding

ion density. Testing over a period of time has indicated that the

energy utilized in the stirring process when considered with

overall cell output actually causes a decrease in overall cell

efficiency rather than an expected increase.

Picking the proper feed point for rod electrodes

can produce a measurable difference in gas production. Observing

the direction of current flow may explain this difference. Two

rod electrodes fed from the same end, produce a smaller amount of

gas per reference input than two rods fed from opposite ends.

New Electrode design reduces cell heating caused by

ion collisions.

A new Barber Pole electrode

design coupled with CRE has moved On Demand

H2+02

(Single Duct, OxyHydrogen) another step

closer to reality. The preceding picture show Series

one experiments that use copper as the electrode material,

while later versions moved into Stainless Steel, Carbon and

Nickel for the active electrode surfaces.

The following image shows the new electrode

design operating with DET (our proprietary additive) and the

vigorous gas release.

Electrode

feed point is critical for optimum operation.

My experiment involved a cell composed of two

carbon rod electrodes. The anode rod was fed from the top end,

which was out of the cell electrolyte and the cathode rod was fed

from its center (within the electrolyte). The following pictures

explain the obvious, all the gas conversion for the cathode is

below the feed point, while the end fed anode produces gas over

its entire length.

The preceding picture shows the two

rods and the yellow wire running down to the center feed point of

the cathode. The bubble action is indicated and can be seen

better in the following images.

This next image shows the anode on the left and

cathode on the right. It is easy to see the O2 bubbles on

the anode as well as the yellow feed wire to the center of the

cathode. Note that there are no H2

bubbles on the cathode above

the feed point.

The following image shows the anode

and cathode below the feed point of the cathode. The bubbles are

indicated and the respective electrodes are marked.

Fully one half of the cathode rod is

useless as it does not produce gas while the entire end fed anode

is producing O2. Without a doubt the way the

electrodes are fed is critical in the operation of the

electrolyzer.

The following image shows a depiction of charge

distribution around three different shapes. The circle is considered

to be a sphere.

The following image shows a 1L beaker

with a Stainless Steel sphere for the cathode and anode of

anodized tin. In this series we measured H2 and O2

production at a rate of 2.13E-2 M/Hr with a pulsed

input of 12.9 volt peak at a 50% duty cycle driven by a CRE switche.

*Note It was

found through many hours of experimentation that there is one and

only one way to determine cell efficiency and that is to measure

the actual production gas volume. It does not suffice to measure

consumed power withing the cell. The consumed power is a valid

parameter in overall efficiency, yet you need to measure gas

output as you vary test parameters. When you find a maximum point

of gas production, then compare cell power (input) with output.

This is a critical fact when you are working with pulsed cells.

Measuring gas volume is not an easy task and requires the storage

of a quantity of gas for a period of time, which presents a

dangerous set of conditions. A limitation on the measurement of

evolved gas it that it does indeed contain water vapor. In order

to obtain fairly accurate measurement, it is recommended that a

Dryer be used, in this way a significant amount of water vapor

can be pulled from the gas mixture. Saving or storage of gas

is not recommended unless you have the proper equipment and

follow strict safety procedure.

C2E2 -

'Charge Cascading Excitation Electrolysis' using Inductive Coupled

Excitation

Having received a number of inquires regarding the

electrolyte used in our various tests, the following is an

enhanced explanation.

I normally use a distilled

water{1}

which is further processed by 'Ozonation', a process that exposes

the water to Ozone to aid in bacterial elimination. This process

is not required by our testing, yet is a process that is

automatically done by our water supplier. We do not produce in

lab distilled water for our testing because we have always felt

it necessary to use water that could be readily available to the

general public for a reasonable price of less than $1.00/gallon.

All water used in our tests (the distilled, treated

water) is degassed for a period of twenty four hours at 500 mmHg.

We do from time to time use a 'Wetting' chemical, a chemical

which aids in the management of water tension. Surface tension

is not of concern, yet the clumping of or large clumped water

molecules will evolve higher gas volumes if they are broken down

to smaller molecule structures. Our primary chemical used for

this purpose is 'Proprietary', although a small amount of standard

dish washing detergent can be used in low level experiments.

For the testing with detergent we recommend that you use

no more than 1.5 mL/L of water.

During our continued testing of electrode geometry,

we found a unique method for viewing the ion impact on various

electrode configurations under different polarity connections.

Because of photographic limitations we are only able to show

images captured from electrodes in free air. The images are

faint, yet clear enough to see the actions taking place.

The following images were captured using a 1cm x

1cm Cu plate and a short, smoothed tip #26 gauge Cu wire. The ion

patterns were displayed by using a special material that

fluoresces upon ion impact.

This is a view of the preceding image, looking down

over the point electrode at a slight angle so as to include the

pattern on the target plate. The image does not show well the

pyramid shaped emission from the point to the plate, yet it

spreads from the point towards the plate, creating the pattern

shown.

What should be observed as very interesting is what happens

when only the polarity of the electrodes is changed. In the

following image the point electrode is Positive and the plate is

Ground.

No pattern on the plate electrode is observed. The

ion flow is a direct straight line between the two electrodes.

The next image is photo enhanced to allow the view of the ion

cloud present, just off of the tip of the wire electrode. The

wire electrode is at the bottom of the image and the dot present

at the top is the point where the ion current enters the Cu plate

electrode. It appears that ionization is greatest just off of the

wire tip, yet declines as it moves towards the plate electrode.

{1}All

examples and tests covered in this text were conducted using an

electrolyte of Distilled H20 with an adjusted pH of

7.00, +/- 0.1. Typical brand was Ozarka (Distilled Water),

Purified by Steam Distillation, Carbon Filtration,

Microfiltration and Ozonation.

{2}The spherical “inverse-square” vector field. Valadimir Rojansky,

“Electromagnetic Fields and Waves”; ISBN: 0-486-63834-0

{11}

Purchased from 'The Graphite Store', http://www.graphitestore.com.

Sizes from 0,25" OD to 0.5" OD were used.

|